Warehouse Dangerous Goods: Label & Placard Requirements

Warehouse Dangerous Goods: Label & Placard Requirements

This is the first part of a two-part series designed specifically for warehouse managers and workers. In this part, we cover the essential labels and placards required for dangerous goods stored or used in your warehouse, lab, or industrial site. The second part will focus on training requirements to ensure everyone handling these materials stay safe and compliant.

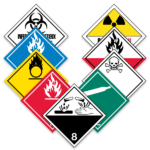

Not Just for Trucks and Large Containers

Placards are not just for transport vehicles or large containers. In a warehouse, laboratory, or storage area, placards are required at the entrance to any space containing dangerous goods, even if the products are not regulated for transportation under the TDG Regulations.

While WHMIS labeling is often sufficient for individual containers, it’s also important to post visible placards that communicate hazards to first responders, particularly firefighters. These placards help responders make critical decisions during emergencies, especially when time and visibility are limited.

Label Requirements

Every container of dangerous goods must display the appropriate label from the time it enters your warehouse until it is used or disposed of.

- Applies to drums, pails, totes, lab containers, and portable tanks

- Labels must be legible, durable, and identify the product’s hazard class

- WHMIS-compliant labels in Canada are acceptable

Tip for Managers: Make label checks as part of your regular inspections, especially after spills or when handling new shipments.

Placard Requirements

Any area where dangerous goods are stored or used must have clear placards posted at the entrance. This includes:

- Storage rooms

- Warehouse aisles

- Laboratories

- Flammable storage lockers

How to Apply Placards Properly

Placards must reflect the product hazards using the TDG classification system. If a product is not regulated under TDG but is classified under WHMIS, it is recommended to use the equivalent TDG placard to communicate the hazard. For example, a Class 8 TDG corrosive placard can be used for a WHMIS only corrosive product.

Here’s how to apply placards:

- If you only have one product in storage: Post the UN number

- Multiple products in the same class: Post the class placard

- Products in different hazard classes: Post a placard for each class, or use a “DANGER” placard as a general warning

Tip for Labs: Space on doors and walls may be limited. In these cases, the requirement focuses more on visibility than the placard size. A visible TDG class placard or “Danger” sign is still necessary to alert staff and responders.

Why This Is Necessary

Placards and labels are not just a formality. They serve as critical warnings that:

- Help firefighters and emergency responders assess danger quickly

- Warn workers and visitors of hazardous materials nearby

Final Reminder

Whether a product is regulated under TDG or only classified under WHMIS, marking the hazard is essential. This isn’t just a paperwork issue; it’s about making sure that emergency responders know what they’re walking into, and that your workers are aware of potential dangers in their workspace.

Always reference both the Transportation of Dangerous Goods Regulations and local fire safety codes when evaluating your warehouse or laboratory.

Stay tuned for the second part of this series, where we’ll cover training requirements for warehouse staff, lab workers, and anyone who handles or stores dangerous goods on-site.

Not sure if you’re compliant? Get expert guidance and training from The Compliance Center. Our team of experts is just a call away for our customers at 855.734.5469 or send us an email, we’re happy to help.

Stay up to date and sign up for our newsletter!

We have all the products, services and training you need to ensure your staff is properly trained and informed.

Hazard Class Labels Hazard Class Labels |

Training Training |