This post was originally published in September 2017 and has been updated in April 2023 for accuracy.

What is Cobb Testing?

If you previously read my blog Anatomy of A box, you learned about the various components that make up a corrugated box. The construction of a box can become even more complicated for dangerous goods. Not only do you need to provide strong, durable corrugated boxes that can withstand drops and movement during transportation, but they must also be able to withstand various weather conditions including snow and rain.

How can box manufacturers and test labs ensure that dangerous goods packaging is safe to use when it gets wet? This is where the Cobb test comes in handy. This test helps determine the quantity of water that can be absorbed by the surface of paper or board in a given time. In this case, the less water that absorbs into the corrugated, the better. In fact as per § 178.516 of CFR 49 as well as TP 14850 7.8 this test is a requirement.

Why Cobb Testing?

Cobb tests are performed, because paper and fiberboard tend to attract and hold water molecules from the surrounding environment. The Cobb test is essential as it tests the ability of the paper to resist the penetration of water and quantity of water absorbed by the surface of fiberboard. If fiberboard absorbs too much water, the box may have difficulty maintaining strength and integrity. In fact, the inner fluting can even separate from the outer linerboard if too much water is absorbed, essentially causing the box to break down. This would be especially problematic for packaging that contains dangerous goods as you can imagine. The key is for box manufactures to create containers using corrugated fiberboard that is able to resist excess water from soaking into the box’s inner structure.

How Does Cobb Testing Work?

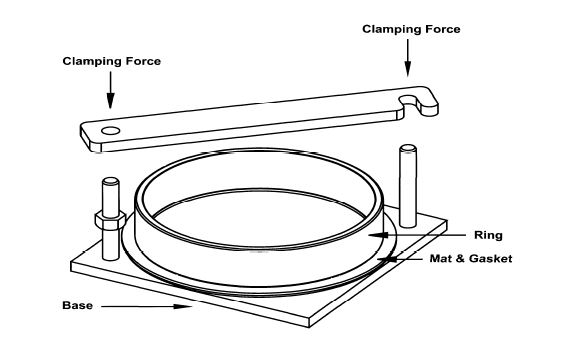

- The corrugated sample is weighed and placed under a vertical cylinder with an internal cross-section of 100 cm². (Figure 1)

- The sample and cylinder rest on a rubber mat supported on a steel plate.

- Approx. 100 ml of water is poured into the cylinder.

- After 30 Minutes, the water is poured out.

- Excess water is removed from the specimen using blotting paper and a roller. (Figure 2)

- The specimen is weighed while wet and the amount of water absorbed by 1 m² of specimen material is calculated.

- In order to receive a passing grade, the water resistance of the outer surface must be such that the increase in mass is not greater than 155 g per square meter over a 30 minute time period.

Fig. 1

Fig. 2

Here is a short video showing the test in action.

Here at ICC Compliance Center, we offer Hazmat Packaging that has all been certified and passed Cobb testing. If you have any questions, please contact ICC Compliance Center at 1.888.977.4834 (Canada) or 1.888.442.9628 (US)

Stay up to date and sign up for our newsletter!

We have all the products, services and training you need to ensure your staff is properly trained and informed.

Custom Packaging Design |

UN Approved Packaging |

UN Packaging Posters & Charts |

So interesting this test, that also has to be completed with others, to ensure the resistance of the cargo during transport.