This post was originally published in July 2015 and has been updated in December 2022 for accuracy.

The Issue

The formalization of the overpack concept into the Canadian TDG regulations has been the subject of concern for domestic shippers of dangerous goods due to the wording for fully regulated (TDGR 4.10.1), limited quantity (1.17 (4)) and excepted quantity (1.17.1 (4)) exemption products. The wording implies that when the Dangerous Goods safety marks for packages within the overpack are not visible, the overpack must have an “OVERPACK” mark displayed. This leads to some additional labelling requirements, particularly for shippers of stretch-wrapped pallet loads.

Definition

We’ll pause to review the concept of an overpack, consistent among the various regulations (e.g. TDG, UN Model Recommendations, IMDG Code, IATA DGR, & 49 CFR).

An overpack is a non-standardized packaging that:

- Is used for handling convenience (e.g. to reduce multiple handling- I.e. 4 drums on a skid, allowing loading 4 at once rather than 4 trips, or 6 small containers in a “non-spec” master carton, or 48 small boxes stretch wrapped on a skid; a keg (small drum) in a non-spec box for stability, etc. )

- Cannot be used as a replacement for inadequate or damaged, required “standardized” packaging

- Is to be unopened between consignor and receiver

- Cannot interfere with the integrity of the standardized packaging (e.g. banding cutting into boxes on a pallet)

The common principle requires that the description of Dangerous Goods that cannot be seen once the overpack is in place will be reproduced on the outside of the overpack.

However, this could be misleading in that someone seeing the Dangerous Goods markings may assume “non-compliance” when there is no package certification mark on the overpack. Although the situation should be fairly obvious with, for example, a stretch wrapped pallet; a master carton situation could be confusing.

Thus, we have the application of the “overpack” mark to signal that the specification package is inside.

Different Strokes

The system starts to get sticky when the wording used in the different regulations is phrased differently.

TDGR 4.10.1 (1) speaks of “the marks on small means of containment”- which implies that each package’s markings must be visible to avoid the need to reproduce them on the overpack. Whereas exemptions TDGR 1.17 (4) – limited quantity and 1.17.1 (4) – excepted quantity speaks of ‘’means of containment’’. The real difference is that a small means of containment implies its size can be less than or equal to 450 L capacity but for the limited quantities and excepted quantities, these have their own size limitations within the applicable article.

Other regulations (49 CFR, IATA DGR, IMDG Code, UN Recommendations) insert the words “representative of…” (all DG or each HazMat) in the overpack. Thus, as long as safety marks representing the individual packages can be seen at least once, there should be no need to reproduce any on the outside of the overpack.

Furthermore, the sequence of the clauses in TDGR 4.10.1 requires the use of an “overpack” mark to be used, regardless of the type of overpack whenever the safety marks are not visible from the outside of the overpack.

The UN Recommendations where the placement of commas in 5.1.2.1 a) implies that the lead-in requirement for an “overpack” mark applies when the DG marks are not visible.

As well, both IATA DGR and IMDG Code requires the word “overpack” to be applied if the DG safety marks are not visible from the outside of the overpack.

49 CFR puts a slightly different spin on things and requires an overpack mark only when DG packages in the overpack which requires a UN specification packaging do not have the marks visible from the outside of the overpack.

Size Matters – Sometimes

The TDGR and 49 CFR both require safety marks on 2 opposite sides if the overpack volume is 1.8 cubic meters (approximately 64 cu.ft.) or more. IATA DGR and IMDG Code are silent on this aspect. All recommend “overpack” letters to be at least 12 mm high as TDGR harmonized as of January 1, 2016.

Other Markings

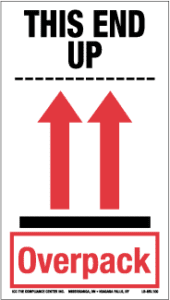

Orientation arrows, as required by all but TDGR, must also be included for liquids. IATA DGR adds a requirement to assign a unique number to each overpack in a consignment when there is more than one. This numbering system is at the shipper’s discretion, but must be referenced on the ‘’Shipper’s Declaration’’ for the consignment.

Limited/Excepted Quantities

Limited and excepted quantities do not require UN specification packaging. However, they do have size limits. For example, a limited quantity package cannot weigh more than 30 kilograms gross, but this would not apply to the overpack as a whole. If you have an overpack such as a crate or skid (which would not be UN specification) handlers could mistake the overpack itself for a exempted package and reject it as too big.

Therefore, TDGR 1.17(4) requires overpacks of limited quantities to display the “OVERPACK” mark as well as the limited quantity mark (unless, of course, the packages with at least one visible limited quantity mark are visible through the overpack.) The same applies to excepted quantities under section 1.17.1(4).

Although there are still some minor variations in regulatory requirements for overpacks, the basic concepts as established in the UN Recommendations on the Transport of Dangerous Goods have brought us to a much more harmonized state.

Stay up to date and sign up for our newsletter!

We have all the products, services, and training you need to ensure your staff is properly trained and informed.

This End Up & Overpack 4.5″ x 8″, Paper, 500/Roll |

Overpack Label, 4″ x 2.75″, Gloss Paper, 500/Roll |

US 49 CFR Publications |

Canadian TDG Publications |

ICC USA

ICC USA ICC Canada

ICC Canada