Pipe Marking for the Faint of Heart

Recently in a GHS for Supervisors class I was asked about pipe markings and where it was stated in the OSHA regulations that they were required. When we look at the OSHA regulations or standards we find that there are not directly any OSHA pipe labeling requirements. However, in 29 CFR 1910.6, which is a list of standards referenced by OSHA, the ANSI A13.1 pipe labeling code requirements are included for some applications and industries. This ANSI pipe marking standard does not apply to buried pipelines or electrical conduit.

If that is the case, then why mark the pipes at all? Why is pipe marking important? Pipe marking ensures that individuals working in the facility are aware of what pipes are carrying as well as any potential hazards associated with the pipe contents. Pipe marking labels indicate which pipelines are dangerous, direction of flow, and pipe contents. And that makes for a safer working environment and lessens the chances of an employee being injured or an unexpected leak into the environment.

When we look at the above standards and I quote: “1910.6(e)(6) – ANSI A13.1-56 Scheme for the Identification of Piping Systems, Included By Reference (IBR) approved for §§1910.253(d)(4)(ii) (welding and cutting gases); 1910.261(a)(3)(iii) (pulp and paper industry); 1910.262(c)(7) (textiles).”

According to the ANSI standards, ANSI separates materials transported in above-ground piping systems into three categories:

- High-Hazard Materials: Encompasses several hazard areas including corrosive and caustic materials; substances that are toxic or capable of creating toxic gases; explosive and flammable materials; radioactive substances; and materials that, if released, would be hazardous due to extreme pressures or temperatures

- Low-Hazard Materials: Materials that are not inherently hazardous and have a small chance of harming employees through mild temperatures and low pressures

- Fire Suppression Materials: Fire protection materials such as foam, carbon dioxide (CO2), Halon and water.

Learn more about our pipe markers »

Does this mean there are not any OSHA pipe labeling requirements outside of the above three areas? No, pipe labeling also falls within the OSHA General Duty clause (Section 5(a)(1) (General Duty Clause) of the OSH Act). What this means is that OSHA, although not directly stated, requires labeling on pipes in compliance with the ANSI A13.1 standard.

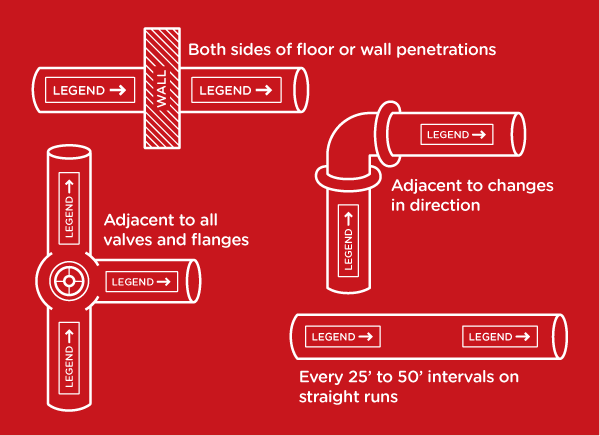

This also reflects that the OSHA pipe labeling requirements are that pipe labels must be placed:

- Adjacent to all valves and flanges

- Adjacent to all changes in pipe direction

- On both sides of wall, floor or ceiling penetrations

- Every 50 feet on straight runs of pipe

Pipe labels must comply with the following color coding:

- Fire quenching fluids – white text on red

- Toxic and corrosive fluids – black text on orange

- Flammable fluids – black text on yellow

- Combustible fluids – White text on brown

- Water – White text on green

- Compressed air – White text on blue

Not only that, but the text size is regulated by the size of the pipe it is placed on. Please check the charts for the text size guidelines based on the size of the pipes in your installations or workplaces. So much for pipe markings not being regulated or required by OSHA.

OSHA usually finds the discrepancies in pipe markings when performing a Workplace Safety Audit (facility inspection). During the facility inspection they examine, not only the pipe marking but, other hazard identification with three questions in mind.

- Do employees understand the potential hazards?

- Do employees know how to avoid the hazards?

- Are the employees aware of what to do in an emergency?

The training for recognizing these potential hazards should be addressed in your Hazardous Communication (HazCom) or Right to Know Training. Normally this training is during orientation or when things or jobs change in the workplace. Employees and contractors have a right to know about the workplace hazards in the areas that they will be working in. The new Globally Harmonized System or GHS regulations address the requirements requiring classification of the hazards.

What is this GHS? The Globally Harmonized System (GHS) is an international approach to hazard communication, providing agreed criteria for classification of chemical hazards, and a standardized approach to label elements and safety data sheets.

OSHA has modified the Hazard Communication Standard (HCS) to adopt the GHS to improve safety and health of workers through more effective communications on chemical hazards. Since it was first promulgated in 1983, the HCS has provided employers and employees extensive information about the chemicals in their workplaces. The original standard is performance-oriented, allowing chemical manufacturers and importers to convey information on labels and material safety data sheets in whatever format they choose.

Adoption of the GHS in the US and around the world will also help to improve information received from other countries—since the US is both a major importer and exporter of chemicals, American workers often see labels and safety data sheets from other countries.

One last thing about GHS that I really like is that there will be a standardized SDS or Safety Data Sheet with 16 sections. The pictograms are pretty universal and tie into the Hazardous Materials labeling and placarding symbols.

Learn more about SDS’s here »

Simply put, pipe marking is one of the most common types of labeling and it is fairly simple. The standards specify the minimum size of the labels and text on the labels. The locations are also specified. A good way to summarize the location requirements is to say that a pipe marker must be visible from any location in the facility. If you can see a pipe, you should also be able to see a label that identifies the pipe contents and direction of flow.

Remember that under the OSH Act, employers are responsible for providing a safe and healthful workplace. More specifically 1910.5(a) Each employer —

(1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

If you need assistance with your pipe marking or any other regulatory needs, please contact us.

ICC USA

ICC USA ICC Canada

ICC Canada