“Packaging had not been closed in accordance with the manufacturer’s closure notification.” Hopefully, you aren’t familiar with the above statement. As I was looking over the common penalties that PHMSA hands out to various dangerous goods shippers, one of the more common enforcements I have seen is not following closing instructions when using UN packaging. If you ship dangerous goods and use UN packaging, you should always be receive closing instructions (also known as packing instructions) from your manufacturer that essentially tell you exactly how to assemble your packaging. For the most part, assembling UN packaging may seem relatively simple, but the slightest oversight can lead to a potentially hefty fine.

Shipper’s responsibility

The 49CFR, 173.22 (4) (i) and (ii) provide clarity regarding closing instructions. For UN packaging, a person must perform all functions necessary to bring the package into compliance with parts 173 and 178 of this subchapter, as identified by the packaging manufacturer or subsequent distributor, for example, applying closures consistent with the manufacturer’s closure instructions. In addition, as the shipper, you are required to maintain a copy of the closure instructions unless they are permanently embossed or printed on the package. This must be made available for inspection by a Department’s representative upon request for at least 90 days once the package is offered to the initial carrier for transportation in commerce. So, if a PHMSA inspector shows up at your door, you are required to have the closure instructions on file for the previous 90 days that you have used the UN-certified packaging. If for some reason, you didn’t receive closure instructions with your UN packaging, or if you lost closing instructions that you previously had on file, you must contact your UN packaging manufacturer immediately and request that they send you the relevant closing instructions for your specific UN packaging.

How to Follow Closing Instructions?

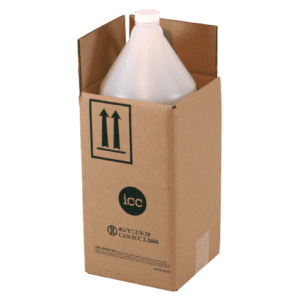

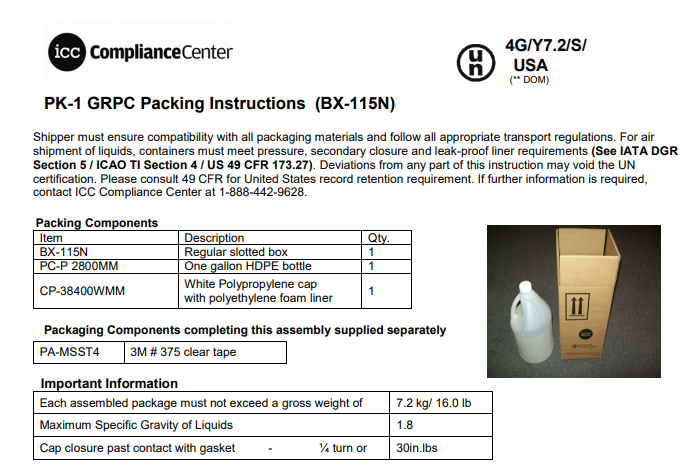

Once you received the correct closure instructions for your UN packaging, now you must follow them closely to remain in compliance with the regulations. And by following closely, I mean exactly, from the type of tape used to the orientation of the inner packaging—for example, our PK-1GRPC 1×1 plastic round gallon shipper.

Here are the closing instructions directly from our website.

The top half of the instructions indicate what the required packing components are. It tells you this combination kit comes with our BX-115N box and our one-gallon plastic round bottle with a cap. It also tells you the specific type of tape required, in this case, 3M #375. Keep in mind that the tape listed in the instructions is the ONLY tape allowed to be used when closing this box. There are no substitutes permitted when it comes to the tape. Also, it mentions the maximum gross weight of the packaging that is allowed (16lbs), along with the specific torque of the cap on the plastic bottle, which is 30 pounds per square inch.

The bottom half of the assembly instructions tells you exactly how to put the package together. For example, it tells you to put one strip of the 3M #375 tape across the center seam and extend at least 2 inches on the side of the box. The assembly also states to tighten the cap to the above torque specifications and place the bottle in an upright position inside the box. Deviation from the assembly below could result in a potential fine by PHMSA. Adding items to the assembly, such as a liner bag or extra absorbent, is allowed as long as you don’t go over the gross weight on the package and it doesn’t affect the structural integrity of the box per PHMSA’s Interpretation at the link below:

https://www.phmsa.dot.gov/regulations/title49/interp/05-0025

Keep in mind that unless you are using a 4GV box, you must ensure that when using your own inner containers, the box you are purchasing is UN tested with a container similar in material and structure to what you are using. For example, the above packaging (PK-1GRPC) was tested with a round plastic gallon bottle, so a round metal paint can would not be an acceptable inner container in this box.

If you ever need assistance in choosing the proper UN packaging for your specific inner container, feel free to contact ICC The Compliance Center at 1-888-442-9628 in the U.S or 1-888-977-4834 in Canada.

Stay up to date and sign up for our newsletter!

We have all the products, services and training you need to ensure your staff is properly trained and informed.

4GV UN Boxes – Variation |

3M #305 Clear Tape |

Liner Bags & Antistatic Bags |

Vermiculite, Grade A4, 4 Cu. Ft. |

ICC USA

ICC USA ICC Canada

ICC Canada