UN Testing: What Makes a 4G Box… a 4G Box?

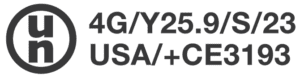

Is a UN rated box really any different than a regular corrugated box? In the physical sense, there may not be much difference at all in terms of the way a UN box looks and feels, but the process involved in the certification of a UN rated box is what makes it a unique type of packaging. If you see a code that looks like below printed on your box, you can rest assured that the box has gone through the necessary testing required to certify it as a UN rated box designed to ship dangerous goods.

There are very specific guidelines that must be followed during the UN testing process that are designed to ensure that your packaging can transport dangerous goods safely enough and prevent any release into the surrounding environment. Below are some of the UN Testing requirements that are required by both The United States (PHMSA) as well as Canada (Transport Canada).

What does UN mean?

Just like in the political world, UN stands for United Nations. These testing requirements that were adopted by both The United States and Canada were introduced by the UN Model Recommendations on the Transport of Dangerous Goods, which provided a basis for the development of harmonized regulations for all modes of transport. Both Transport Canada and PHMSA took elements from the UN Model recommendations when it comes to creating their own specific UN testing requirements.

What are the Requirements of UN Testing?

Conditioning

Once the packaging components are sent to the lab, the outer 4G box must undergo a conditioning process that is required per the 49CFR at 178.602 (d), and TP14850 at 7.3.1. These boxes must be conditioned for 24 hours at a specific humidity and temperature per both regulations.

Drop Test

Per the 49CFR 178.603 and The TP14850 7.4, drop testing is required for all packaging design types. The drop height is determined by the packing group (X, Y, or Z) and there are 5 fully assembled box samples each containing the appropriate inner packaging at a specific weight. Each box is dropped in a different orientation which includes the top, bottom, long side, short side, and corner. In order to pass, there can’t be any leakage of the inner containers and the outer box itself must not exhibit any damage that is likely to affect safety during transport. Inner packaging must remain completely inside of the outer box after being dropped.

Vibration Standard

This test is required by the 49CFR at 178.608 but is not required by Transport Canada. Essentially 3 fully assembled sample packages are placed on a vibration table for 1 hour. In order to pass this test, there should be no rupture or leakage in the packaging when the packaging is turned on its side immediately following the test.

Stacking Test

Three fully assembled sample boxes must undergo a stacking test which subjects a force applied to the top surface of each box equivalent to the total weight of identical packages that may be stacked on it during transport. This test is required per the 49CFR at 178.606 and the TP14850 7.5. For a packaging to pass, the test sample may not show any deterioration which could adversely affect transportation safety or any distortion likely to reduce its strength and no leakage.

Cobb Test

Previously, I wrote a blog explaining the specifics of Cobb testing, in which all 4G boxes are required to be capable of passing per both the 49CFR 178.516 and TP14850 7.8.

This test determines the water resistance/absorption of the outer surface of the 4G box and is 30 minutes long. There is a specific formula located in both regulations that helps the test lab determine if the fibreboard passes or fails.

Hydrostatic Pressure Test

In addition to these tests, if you are shipping liquids by air, you must make sure that the inner containers are capable of withstanding a 95KPA pressure differential required by IATA 5.0.2.9. I wrote an extensive blog on this topic as well. This test itself wouldn’t be required when the UN is certifying a 4G box, but it is important that your inner containers containing liquid are capable of meeting the 95KPA threshold to meet the IATA requirement.

ICC has a wide variety of inner containers that are capable of meeting this pressure test standard, and all of our 4G boxes have been tested in accordance with the various dangerous goods regulations. Check out our line of 4G packaging.

Do you have questions about UN Packaging? Take a look at our UN Packaging FAQ or download our Packaging Infographic.

You can contact our team of experts at 855.734.5469 or send us an email, we’re happy to help.

Stay up to date and sign up for our newsletter!

We have all the products, services, and training you need to ensure your staff is properly trained and informed.

Custom Packaging Design Custom Packaging Design |

UN Approved Packaging UN Approved Packaging |

49 CFR Publications 49 CFR Publications |

ICC USA

ICC USA ICC Canada

ICC Canada